Why do you need pilot arc in plasma cutter?

Feb 07, 2024

Pilot arc and ordinary plasma cutting are two techniques used in the process of plasma cutting, a method that uses a high-velocity jet of ionized gas to cut through electrically conductive materials. Let's explore both concepts:

1. Ordinary Plasma Cutting:

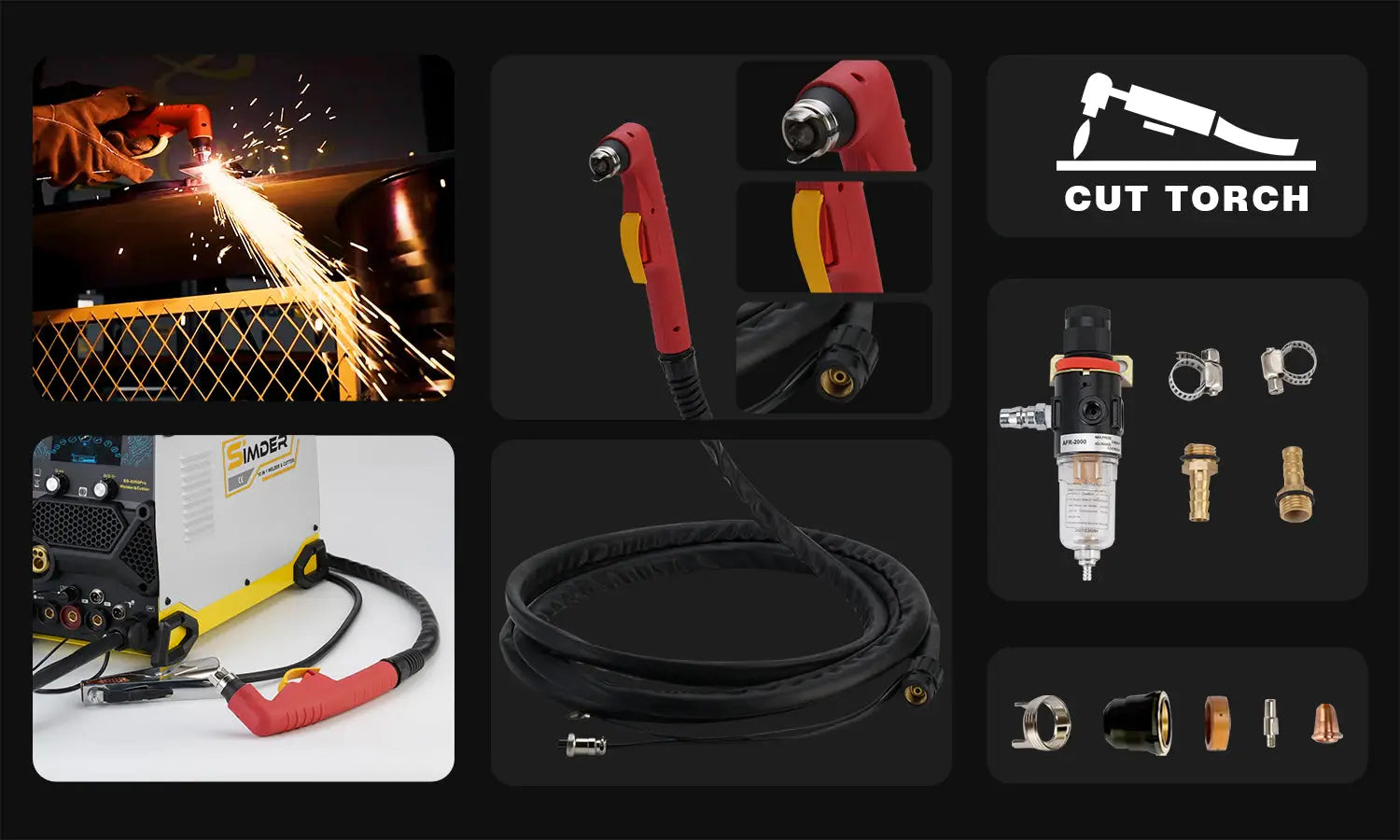

In ordinary plasma cutting, a high-frequency electrical arc is used to ionize the gas, typically compressed air, creating a plasma state.

The plasma jet generated is then directed toward the workpiece, and the high-temperature plasma melts the material and blows away the molten metal, resulting in a clean and precise cut.

This method is effective for cutting a variety of materials, including steel, aluminum, copper, and other conductive metals.

2. Pilot Arc Plasma Cutting:

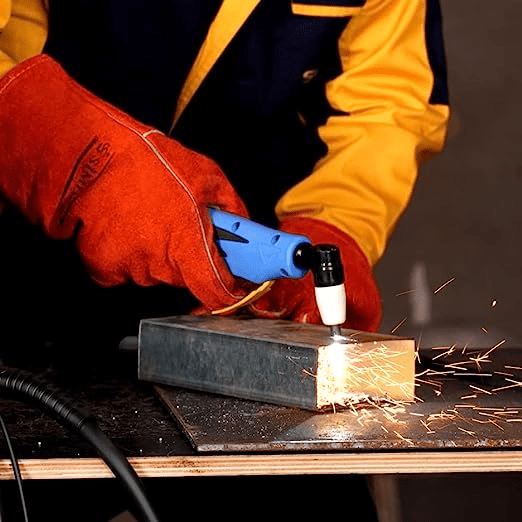

Pilot arc plasma cutting uses a different approach in terms of initiating the plasma arc.

Instead of directly touching the workpiece with the electrode to create the arc, a pilot arc is established first, independent of the workpiece.

The pilot arc is a low-current, high-voltage discharge that forms between the electrode and a nozzle. This arc ionizes the gas, creating the plasma state.

Once the pilot arc is established, it can be transferred to the workpiece by bringing the electrode in contact with the material. This allows for a stable and continuous cutting process.

|

|

Regular Plasma Cutter | Pilot Arc Plasma Cutter |

| Arc Initiation | by bringing the electrode in direct contact with the workpiece. | initiates a low-current, high-voltage pilot arc independent of the workpiece. |

| Electrode Wear | This direct contact can cause wear and tear on the electrode, leading to shorter consumable life. | This can result in a longer lifespan for consumables. |

| Application and Material Considerations | suitable for a wide range of applications and materials, especially when a direct contact arc initiation is not a limitation. | preferred when cutting painted or coated materials, perforated metals, or in situations where maintaining an arc on the workpiece may be challenging. |

| Cost and Complexity | simpler and may be less expensive. | often more complex and can be more expensive. |

| Versatility | versatile and suitable for various applications, making them common in many metal cutting scenarios. | versatile as well and may be chosen for specific applications where the benefits of a pilot arc, such as extended consumable life and improved arc stability, are crucial. |

Having said so many benefits of pilot arc plasma cutter, does SSimder have such a machine?

Certainly!

The Upgraded SD-4050Pro[2024] did it.

Pilot Arc Plasma Cutting

- Non-touch Pilot Arc Ignition

- Pilot Arc Current Adjustment

- Post Gas Adjustment

- 2T/4T Adjustment

- Smart Memory Supported

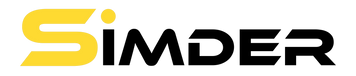

Plasma Cutting Torch

- Upgraded Non-Touch Pilot Arc

- Length: 4 meters (13.12 feet)

- Exquisite workmanship, pursuit of quality

- Specifically suitable for Upgraded SD-4050Pro[2024]

- For use with IPT40 Pilot ARC Plasma Cutting Consumables+

What can you do with such a 10-in-1 welder&cutter machine?

- Metal repair and welding:

Repair metal items in your home such as doors, railings, garden tools or bicycles.

Weld metal parts to restore their structural strength.

- Home construction and renovation:

Install and repair metal door frames, fences or stair railings.

Make or repair furniture, ladders and other metal structures.

- Garden and outdoor projects:

Make garden ornaments, planters, yard art or gardening tools.

Repair and strengthen outdoor metal structures such as patio doors, fences or grills.

- DIY craft and art projects:

Create personalized metal art, sculptures or wall hangings.

Get creative with home craft projects such as making metal frames, handmade gifts, and more.

Read more about How does a plasma cutter work→